Quad 1000/1001 mounting recommendations

MOUNTING

QUAD 1000 / QUAD 1001 HV is designed to be used either on a busbar or connected directly to a work coil.

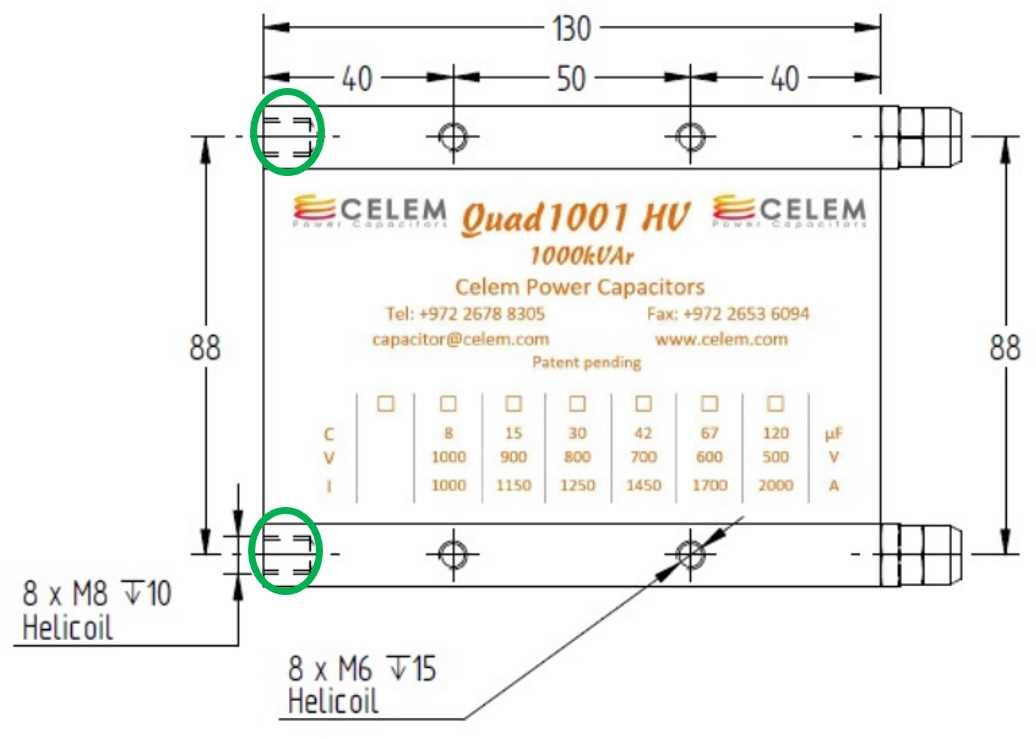

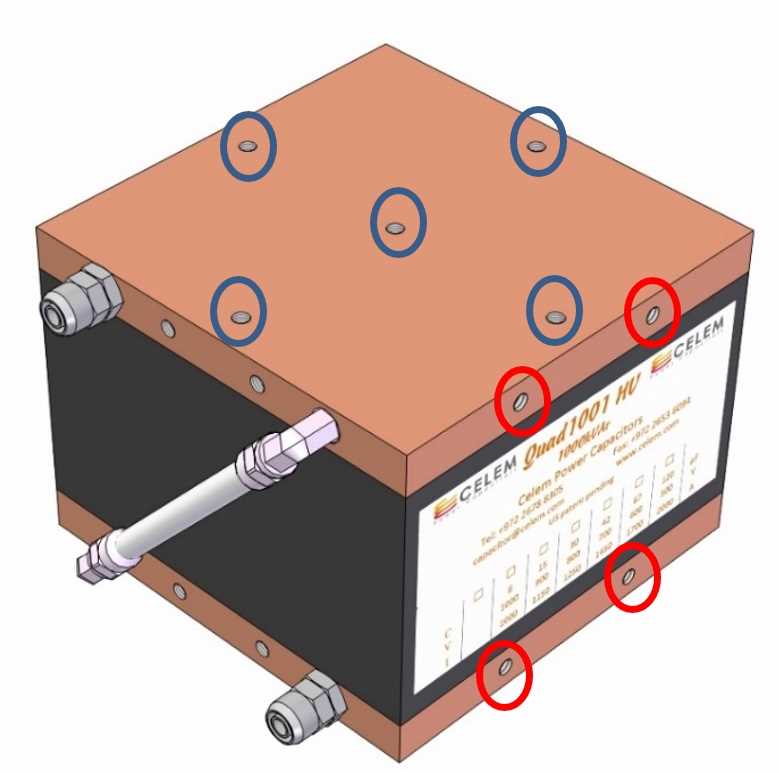

Direct connection to work coil can be performed using 8 x M8 holes with hellicoil, see green ellipses in sketch below.

Mounting on a busbar can be done either from the side (using 4 M6 screws, see red ellipses in the photo below) or from top and bottom (using 10 M6 screws, see blue ellipses for top connection in the photo below).

COOLING

- QUAD 1000 / QUAD 1001 HV capacitors have dielectric as well as Ohmic losses.

- The dielectric inside QUAD 1000 / QUAD 1001 HV capacitors is polypropylene. Polypropylene can be heated up safely to 90°C during operation without any degradation. When this temperature is achieved at the hottest point of capacitor’s core, the external temperature of the capacitor’s surface is 45 - 50°C.

- The dielectric losses of Polypropylene are P* tan delta, Px2^10-4.

- The ohmic losses result from conductors inside the capacitor and conduction to the busbar.

- Total losses of a mounted QUAD 1000 / QUAD 1001 HV for cooling purposes should be calculated as 1/1000 of the power, one should expect that 1000 kVAr capacitor at full power will generate 1000W of heat.

- Water flow of 1 liter/minute when dissipating 1kW will be heated by 14 degrees C. (calculated by specific heat of water). This ratio enables to calculate the desired water flow, once power losses and water inlet temperature are given.

- Maximum inlet water pressure in Celem water cooled capacitors is 5 Bar.

- The outlet water temperature should not exceed 45°C.

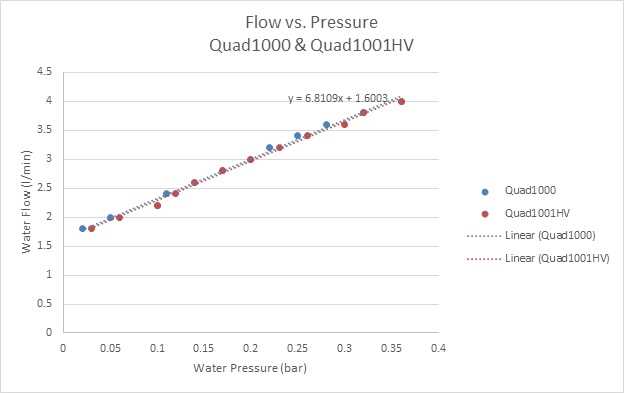

- Better cooling can be achieved either by using colder water, or by increasing the flow, see flow vs. pressure graph below.